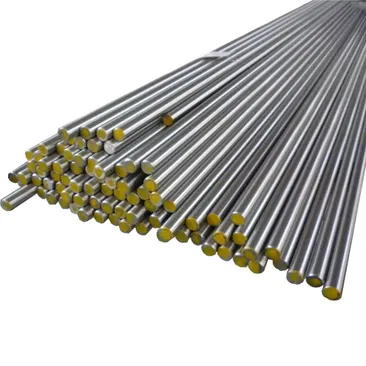

A214 is a steel grade produced according to American ASTM standards, which belongs to American standard.

Now the common round steel processes are hot rolling, forging and cold drawing. The steel quality and application scope of these three processing modes will also have some differences. For example, the specification of hot rolling is generally 5.5-250MM, and the appropriate steel can be selected according to the actual needs.

Generally, parts are manufactured by machinery or used as seamless steel pipe blanks, and steel is also used in some building construction.

Round steel has relatively high strength, high hardenability and very good toughness, so its pressure bearing capacity is also guaranteed. Even if it is used at high temperature, the creep strength is high and the durability is also guaranteed.

|

Material

|

A214 |

|

Thickness

|

0.1mm-300mm or as required

|

|

Standard

|

AISI,ASTM,DIN,BS,JIS,GB,JIS,SUS,EN,etc.

|

|

Technique

|

Hot rolled,cold rolled

|

|

Surface Treatment

|

Clean, blasting and painting according to customer requirement

|

|

Thickness tolerance

|

±0.1mm

|

|

Application

|

It is mainly used to make structural parts such as car girder, beam, transmission shaft and car chassis parts, which can reduce the weight of the parts.

|

|

Shipment time

|

Within 7-15 workdays after receiving deposit or L/C

|

|

Export packing

|

Waterproof paper, and steel strip packed.

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required

|

|

Capacity

|

250,000 tons/year

|

Round steel belongs to carbon structural steel for construction and machinery, while square steel belongs to carbon structural

steel for machinery. Both of them are simple section steel, and their section shapes are respectively round and square. Low carbon is mainly used for

drawing wire, forging rivets, bolts, nuts and other metal products of raw materials. Medium carbon round steel and square steel

are generally used to make mechanical structural parts.

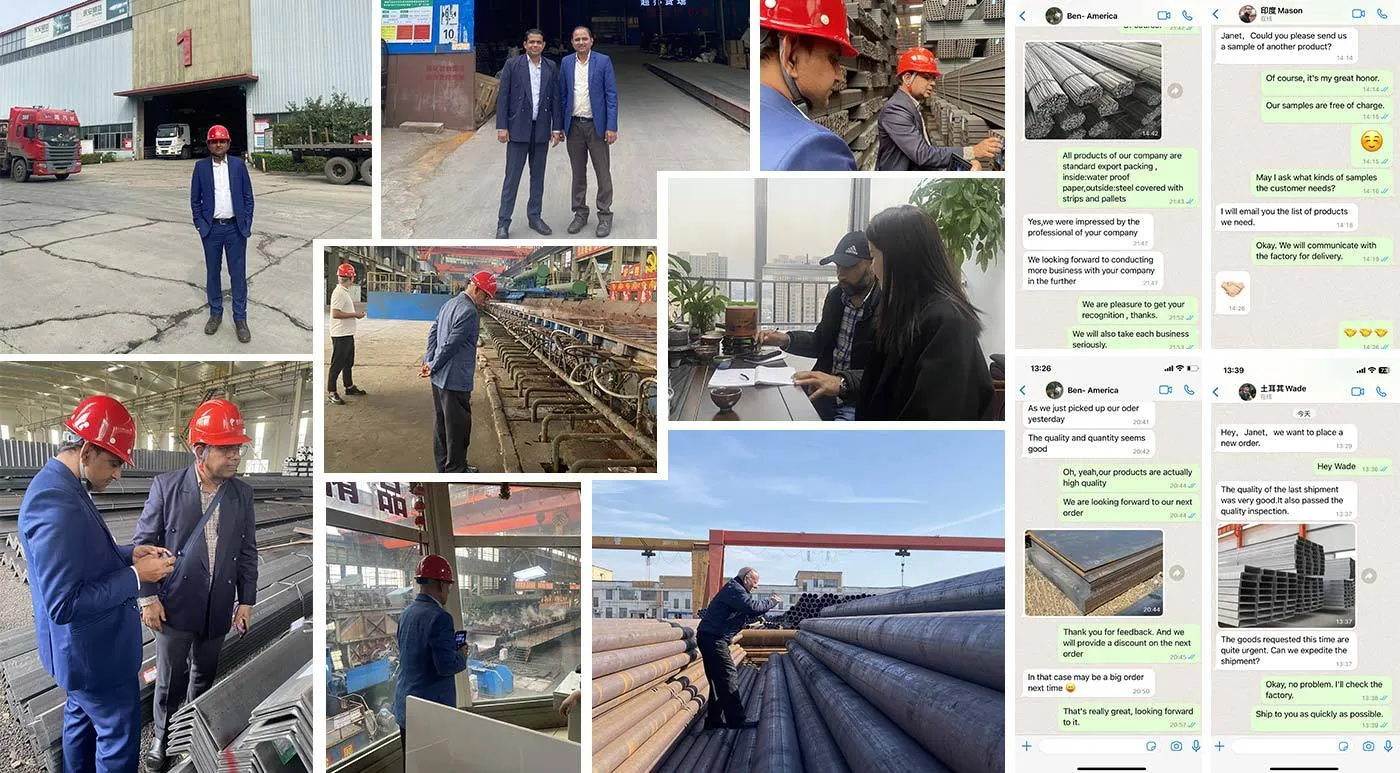

Customer group photo

Production process

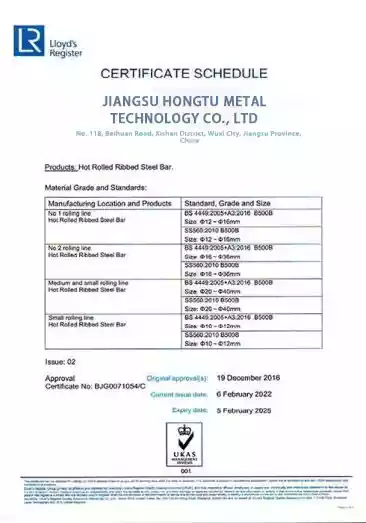

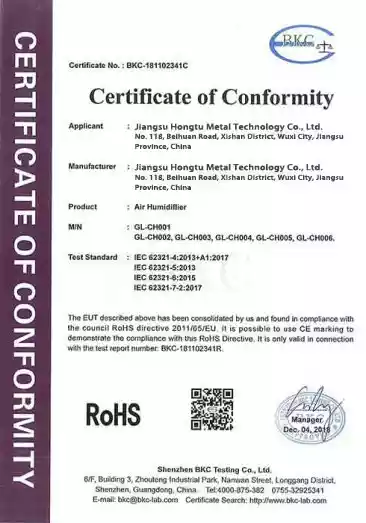

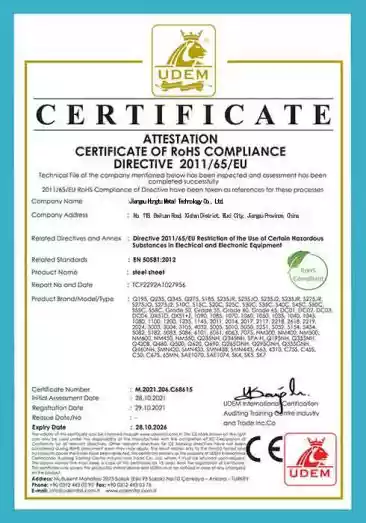

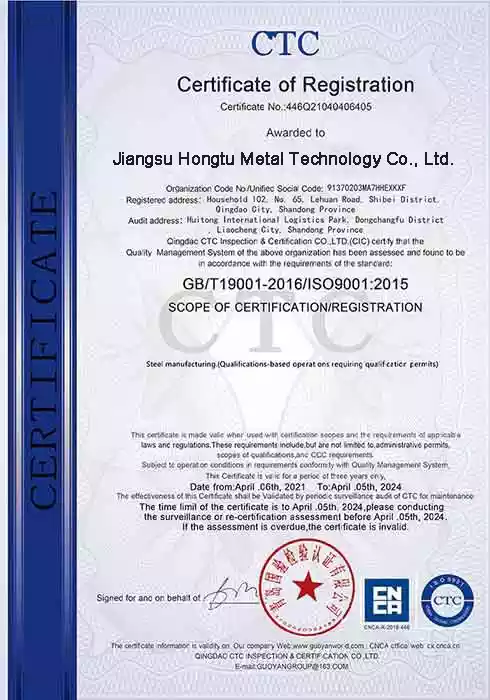

Qualification certificate