Product introduction

Structural Steel Pipe

Pipe Type: Structural Pipe, Structural Seamless Pipe, Seamless Structural Pipe

Application: In Structural Engineering and Construction Industry

Specification: OD: 1/8'' ~ 26'' (10.3 ~ 660mm)

WT: SCH 10 ~ 160, SCH STD, SCH XS, SCH XXS

LENGTH: Fixed Length (5.8/6/11.8/12mtr), SRL, DRL

Standard: ASTM A53/A252/A500/A501, JIS G3444, EN 10210/10219

Ends: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Specification of Structural Steel Pipe

| API 5L/ASTM A106 GR.B, Structural Steel Pipe |

公称通径

DN |

外径OD(mm) |

SCH40(6m/5.8m) |

SCH40(6m/5.8m) |

SCH40(6m/5.8m) |

| 壁厚WT |

壁厚WT |

壁厚WT |

| (mm) |

(mm) |

(mm) |

| 1/4'' |

13.7 |

2.24 |

3.02 |

/ |

| 3/8'' |

17.1 |

2.31 |

3.2 |

/ |

| 1/2'' |

21.3 |

2.77 |

3.73 |

4.78 |

| 3/4'' |

26.7 |

2.87 |

3.91 |

5.56 |

| 1'' |

33.4 |

3.38 |

4.55 |

6.35 |

| 1-1/4'' |

42.2 |

3.56 |

4.85 |

6.35 |

| 1-1/2'' |

48.3 |

3.68 |

5.08 |

7.14 |

| 2'' |

60.3 |

3.91 |

5.54 |

8.74 |

| 2-1/2'' |

73 |

5.16 |

7.01 |

9.53 |

| 3'' |

88.9 |

5.49 |

7.62 |

11.13 |

| 3-1/2'' |

101.6 |

5.74 |

8.08 |

/ |

| 4'' |

114.3 |

6.02 |

8.56 |

13.49 |

| 5'' |

141.3 |

6.55 |

9.53 |

15.88 |

| 6'' |

168.3 |

7.11 |

10.97 |

18.26 |

| 8'' |

219.1 |

8.18 |

12.7 |

23.01 |

| 10'' |

273 |

9.27 |

15.09 |

28.58 |

| 12'' |

323.8 |

10.31 |

17.48 |

33.32 |

| 14'' |

355.6 |

9.53 |

11.13 |

19.05 |

| 16'' |

406.4 |

9.53 |

12.7 |

21.44 |

| 18'' |

457 |

9.53 |

14.27 |

23.83 |

| 20'' |

508 |

9.53 |

15.09 |

26.19 |

| 24'' |

610 |

9.53 |

17.48 |

30.96 |

Technical data

Structural Steel Pipe Chemical Composition and Mechanical Properties

| Standard |

Grade |

Chemical Composition (%) |

Mechanical Properties |

| ASTM A53 |

C |

Si |

Mn |

P |

S |

Tensile STrength(Mpa) |

Yield STrength(Mpa) |

| A |

≤0.25 |

- |

≤0.95 |

≤0.05 |

≤0.06 |

≥330 |

≥205 |

| B |

≤0.30 |

- |

≤1.2 |

≤0.05 |

≤0.06 |

≥415 |

≥240 |

| ASTM A106 |

A |

≤0.30 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥415 |

≥240 |

| B |

≤0.35 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥485 |

≥275 |

| ASTM A179 |

A179 |

0.06-0.18 |

- |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

| ASTM A192 |

A192 |

0.06-0.18 |

≤0.25 |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

| API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

≥331 |

≥207 |

| B |

0.28 |

- |

1.20 |

0.030 |

0.030 |

≥414 |

≥241 |

| X42 |

0.28 |

- |

1.30 |

0.030 |

0.030 |

≥414 |

≥290 |

| X46 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥434 |

≥317 |

| X52 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥455 |

≥359 |

| X56 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥490 |

≥386 |

| X60 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥517 |

≥448 |

| X65 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥531 |

≥448 |

| X70 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥565 |

≥483 |

| API 5L PSL2 |

B |

0.24 |

- |

1.20 |

0.025 |

0.015 |

≥414 |

≥241 |

| X42 |

0.24 |

- |

1.30 |

0.025 |

0.015 |

≥414 |

≥290 |

| X46 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥434 |

≥317 |

| X52 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥455 |

≥359 |

| X56 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥490 |

≥386 |

| X60 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥517 |

≥414 |

| X65 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥531 |

≥448 |

| X70 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥565 |

≥483 |

| X80 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥621 |

≥552 |

Structural Steel Pipe Chemical Composition and Mechanical Properties

| Standard |

Grade |

Chemical Composition |

Mechanical Properties |

| C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

Elongation(%) |

| GB/T8163 |

10 |

0.07-0.14 |

0.17-0.37 |

0.35-0.65 |

≤0.035 |

≤0.035 |

≤0.15 |

≤0.25 |

≤0.25 |

335-457 |

≥205 |

≥24 |

| 20 |

0.17-0.24 |

0.17-0.37 |

0.35-0.65 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.25 |

≤0.25 |

410-550 |

≥245 |

≥20 |

| Q345 |

0.12-0.20 |

0.20-0.55 |

1.20-1.60 |

≤0.045 |

≤0.045 |

- |

- |

- |

490-665 |

≥325 |

≥21 |

Structural Steel Pipe Tolerance

| Pipe types |

Pipe Szie(mm) |

Tolerances |

| Hot rolled |

OD |

All |

±1% (min ±0.50mm) |

| WT |

All |

+15%, -12.5% |

| Cold drawn |

OD |

6~10 |

±0.20mm |

| 10~30 |

±0.40mm |

| 30~50 |

±0.45mm |

| >50 |

±1% |

| WT |

≤1 |

±0.15mm |

| >1~3 |

+15% -10% |

| >3 |

+12.5% -10% |

Structural Steel Pipe End

| Plain End |

Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Plain End (Square Cut) |

Wall Thickness over 0.5 inch, including SCH XXS |

| Beveled End |

Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Couplings |

Outside Diameter equal or less than 2'' |

| Thread Protection |

Outside Diameter over 4 inch |

Customer group photo

Production process

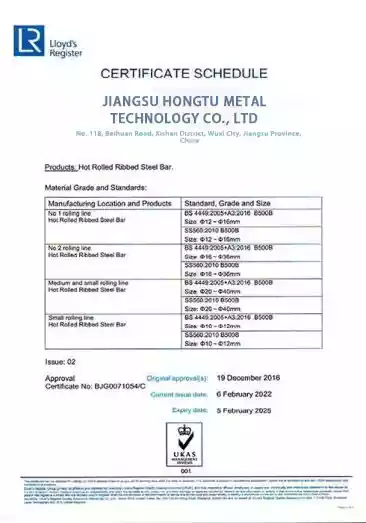

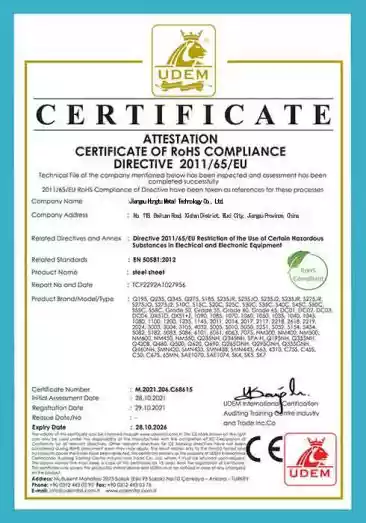

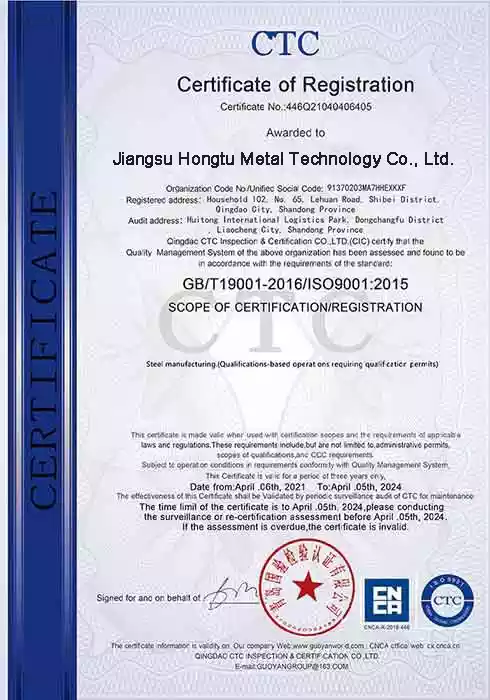

Qualification certificate