1.4529 stainless steel pipe is commonly utilized in applications requiring superior corrosion resistance in highly corrosive environments containing acids, chloride ions, and seawater. Its primary use includes manufacturing components for chemical processing plants, offshore oil and gas platforms, desalination plants, and pulp and paper industries, where resistance to corrosion and pitting is essential. Additionally, it finds utility in industries such as marine engineering, where it can withstand exposure to harsh marine environments. Its high levels of chromium, nickel, and molybdenum contribute to its exceptional corrosion resistance properties, making it suitable for critical applications where reliability and performance in corrosive environments are paramount.

|

1.4529 stainless steel pipe

|

|

Standard

|

Food Grade Sanitary Tube: JIS G3447, KS D 3585, ASTM A270, EN 10357(DIN 11850), AS 1528.1, ISO 2037(NF A49-249)

|

|

Heat exchanger tube: ASTM A249 / ASME SA249, GB / T 24593-2009, HG 20537.2

|

|

Industrial pipe: ASTM A312, EN 10217-7, GB / T 12771-2008, HG 20537.3

|

|

Drinking water tube: GB / T 19228

|

|

Mechanical tube: ASTM A554, EN 10296-2

|

|

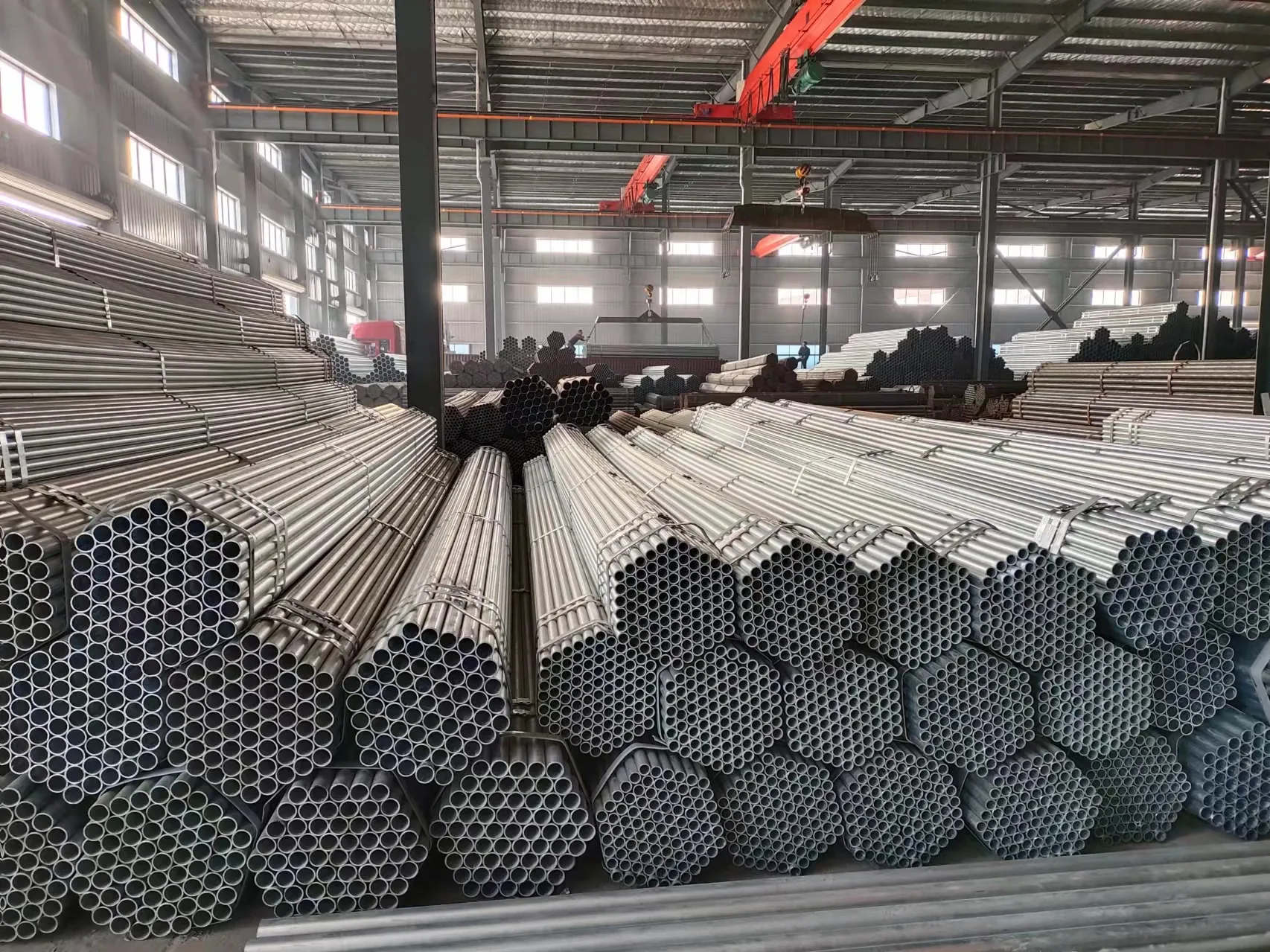

Size

|

Outer Diameter Range: 9.5~2000mm

Thickness Range: 0.5~20mm (Size can be customized.)

Length: Up to 18.3 meters per piece.

|

|

Shape Section

|

Round, square, rectangular

|

|

Usage

|

Sanitary tubing: for food processing industry, beverage industry, sugar mill and so on;

Heat exchanger tube: condenser, boiler, super heater, evaporator and so on;

Industiral pipe: for petroleum delivery, gas delivery, petrochemical industry, wastewater treatment, drainage system, and so on;

Mechanical tube: handrail, railings, balustrade, hence and so on.

|

Features:

1.Our stainless steel tubes pipes are treated by bright annealing, inside weld bead removing, precise polishing. The roughness of tubes could be under 0.3μm.

2.We have the non destructive testing ( NDT ), eg. online eddy current inspection and hydraulic or airtightness testing.

3. Thick welding, good appearance.The mechanical properties of tube could be tested.

4. The raw material is from Taigang, Baogang, Zhangpu and so on.

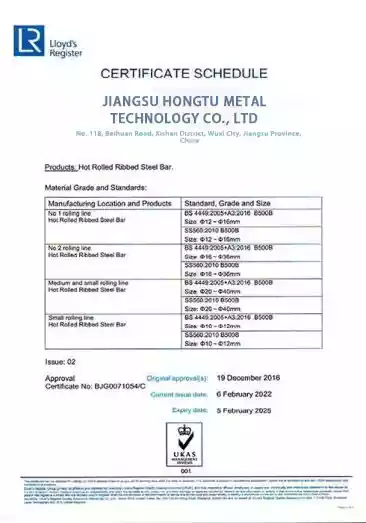

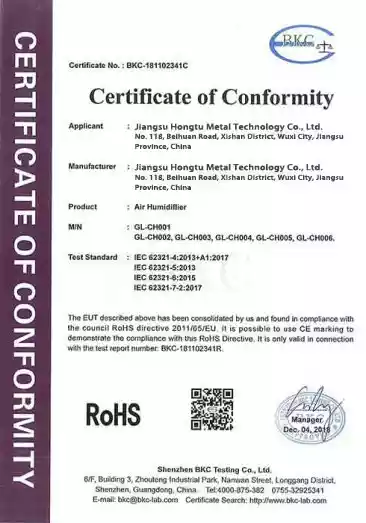

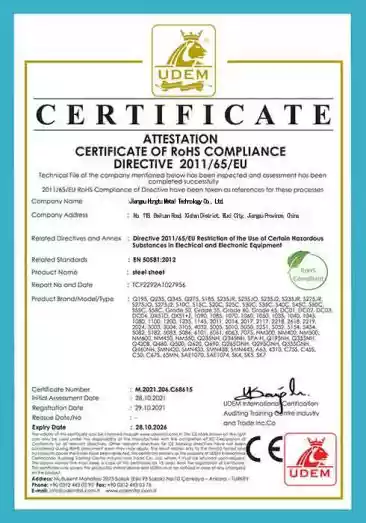

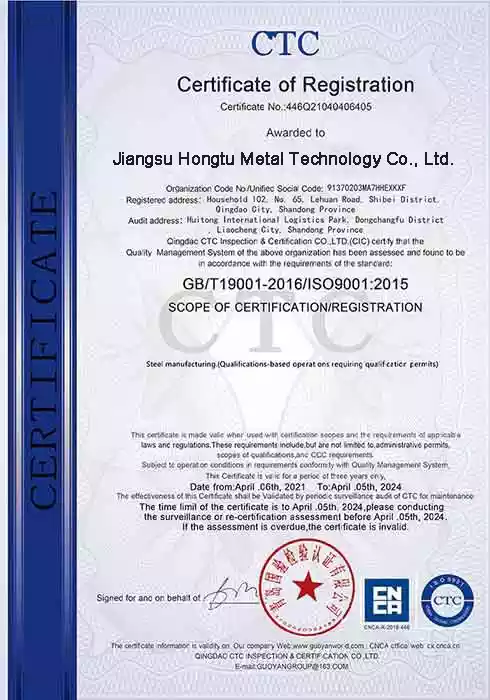

5. And Our tubes are certificated by AD 2000-W0, PED 2014/68/EU, ISO 9001 : 2015.

6. Full material traceability is guaranteed during the manufacturing process.

7. Polished tube is supplied in individual plastic sleeves with capped ends ensuring optimum cleanliness.

8. Internal Bore: Tubes have a smooth, clean and crevice free bore.

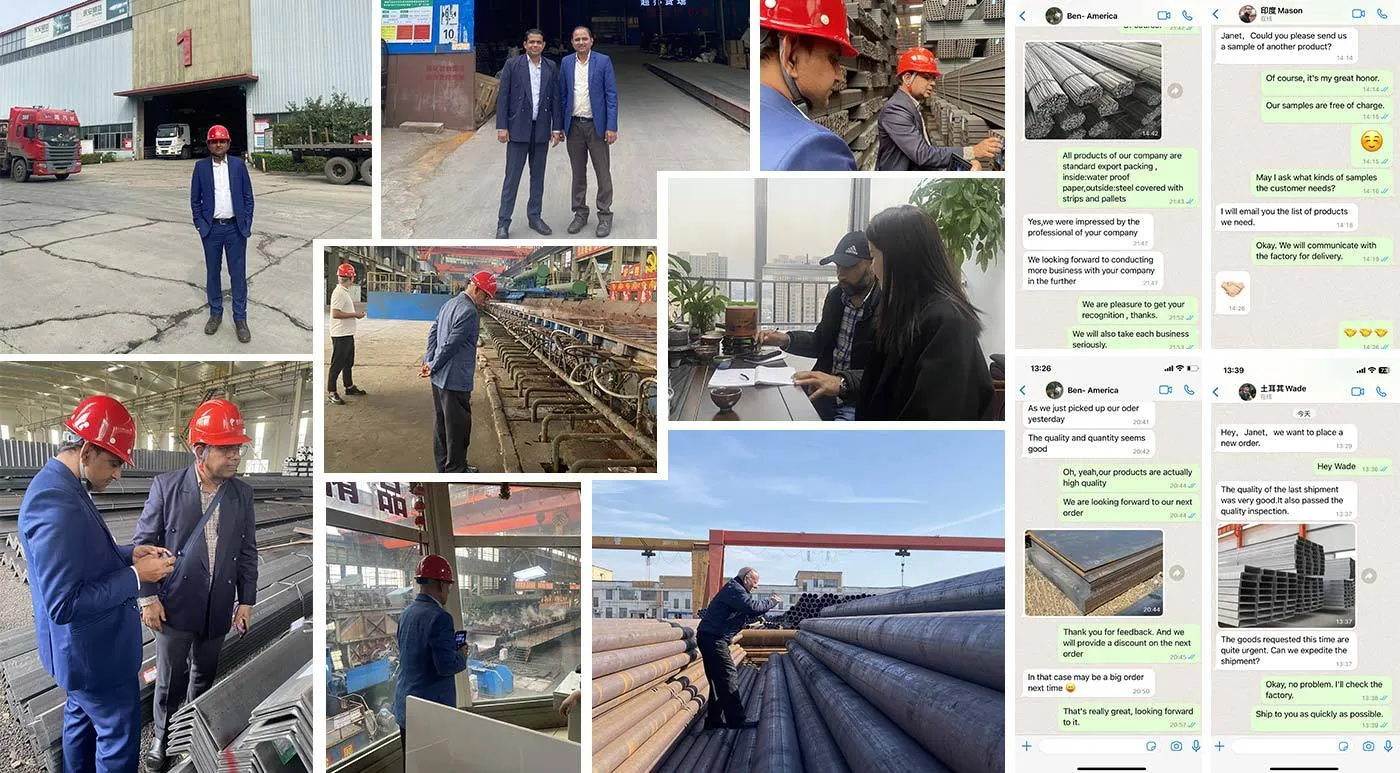

Customer group photo

Production process

Qualification certificate