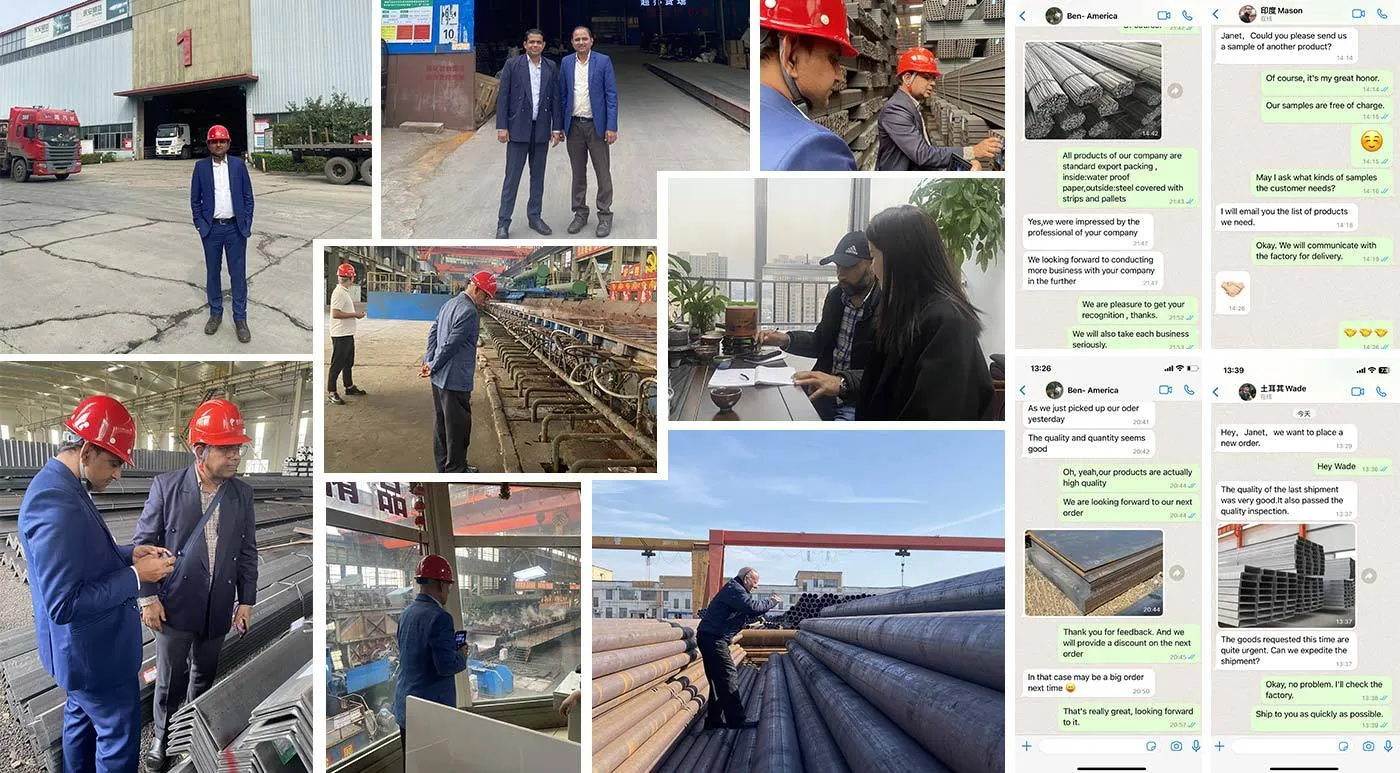

Warehouse Storage

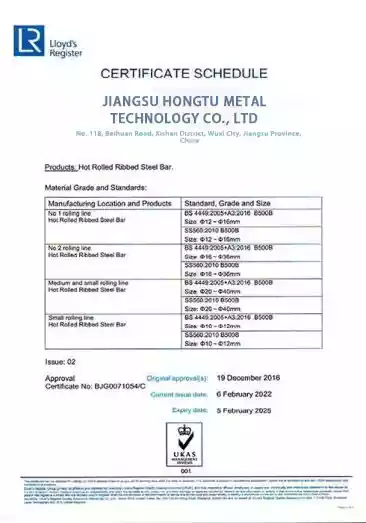

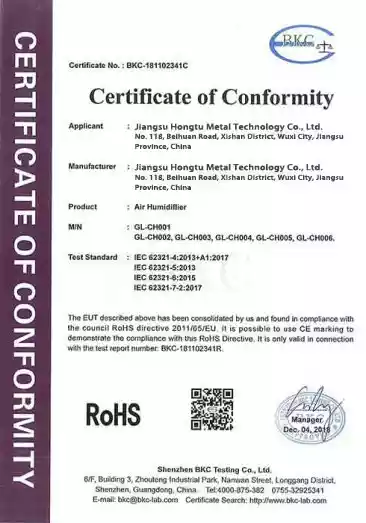

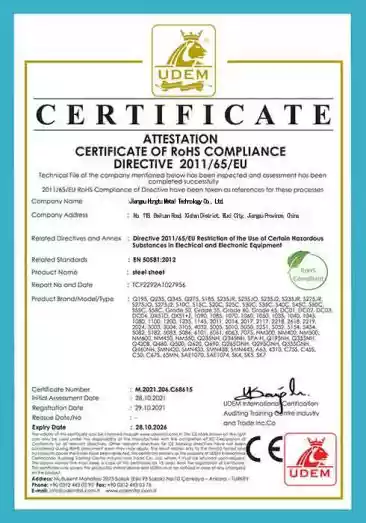

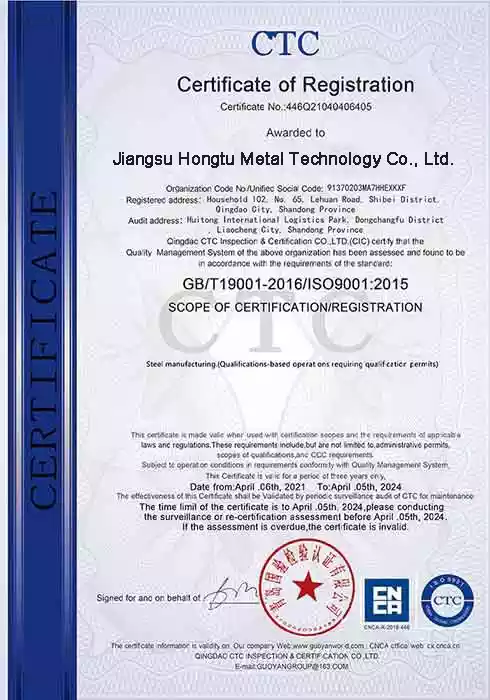

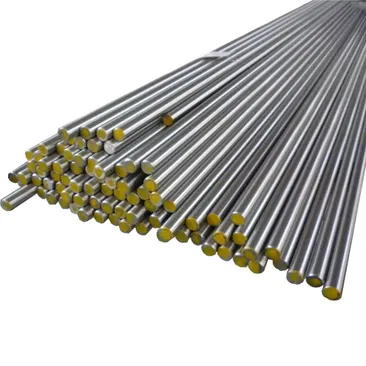

The predecessor of Jiangsu Hongtu Metal Technology Co., Ltd. . founded in 2012, it belongs to Industry Bureau of Jiangsu . Aims to promote the development of Stainless / Carbon steel industry of Jiangsu . Now the main business scope of our company covers various kinds of Stainless steel and carbon steel materials , such as hot rolled / cold rolled stainless steel coils / sheet , Seamless / welded stainless steel pipe ( tube ).

Packing and shipping

As the leading provider of steel materials in Jiangsu , we have our own factories as follows : A seamless stainless steel pipe factory located in Wuxi . A welded stainless steel tube factory located in Wuxi . A stainless steel coil processing workshop in for Slitting , winding & unwinding of steel coils . A cold rolling seamless steel pipes in Wuxi for cold rolled seamless steel pipes . We provide the products consultation , purchase plan suggestion , logistic service ( including the shipment service , custom works , etc ).

Application field

We will provide you with the shortest lead time on the basis of quality and quantity; "Integrity" is the only principle of the company, and "win-win" is the direction pursued. We will always serve you enthusiastically and look forward to long-term cooperation with you.