|

Item

|

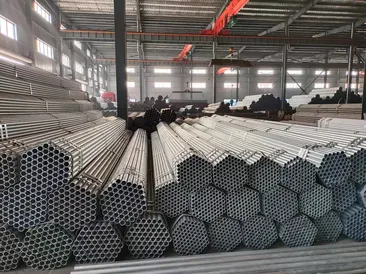

Galvanized Pipe

|

|

Length

|

1-12m or as required

|

|

Width

|

0.6m-3m or as required

|

|

Thickness

|

0.1mm-300mm or as required

|

|

Standard

|

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc.

|

|

Technique

|

Hot diped , Electroplating diped

|

|

Surface Treatment

|

Clean, blasting and painting according to customer requirement

|

|

Thickness tolerance

|

±0.15mm

|

|

Coatings

|

Top Coats :5 micron primer + 20 micron colour

Back Coat: 5 micron primer – 7 micron primer

|

|

Export packing

|

Waterproof paper, and steel strip packed.

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required

|

Hot-dip galvanized steel pipes are widely used in the manufacturing industries of construction, machinery, coal mining, chemical industry, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery, shed construction, etc.

Galvanized steel pipe has a welded steel pipe with a hot dip or electro galvanized layer on the surface. Galvanization can increase the corrosion resistance of steel pipes and prolong the service life. Galvanized steel pipe has a wide range of uses, in addition to being used as a pipeline for general low pressure fluids such as water, gas and oil, it is also used as an oil well pipe and oil pipeline in the petroleum industry, especially in the marine oil fields, as an oil heater, condensation cooler and coal distillation and oil washing exchanger pipe for chemical coking equipment, and as a support frame pipe for trestle piles and mining pits, etc.

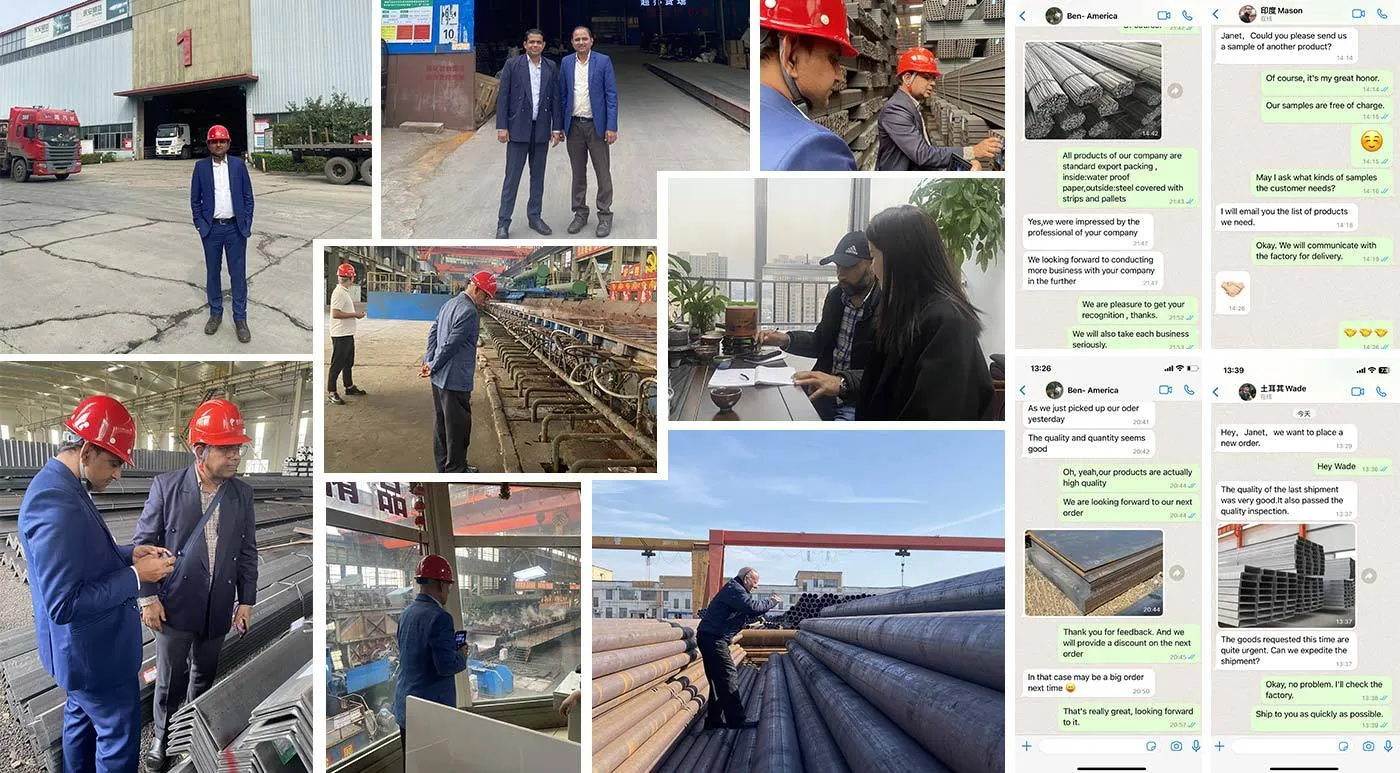

Customer group photo

Production process

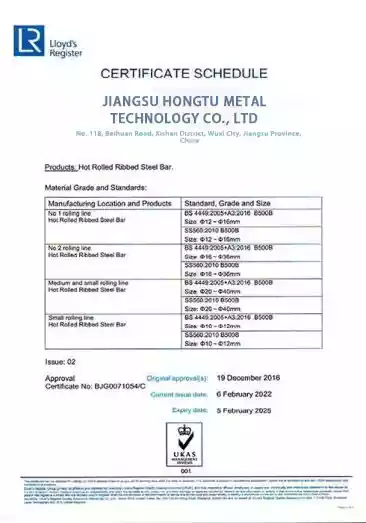

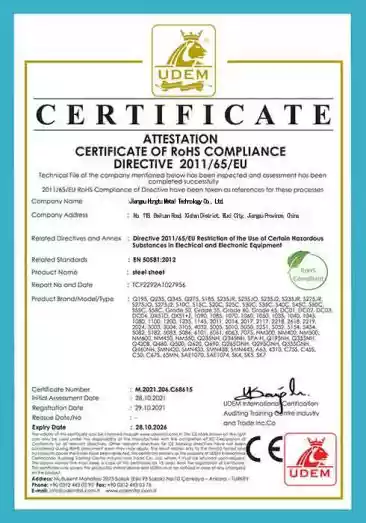

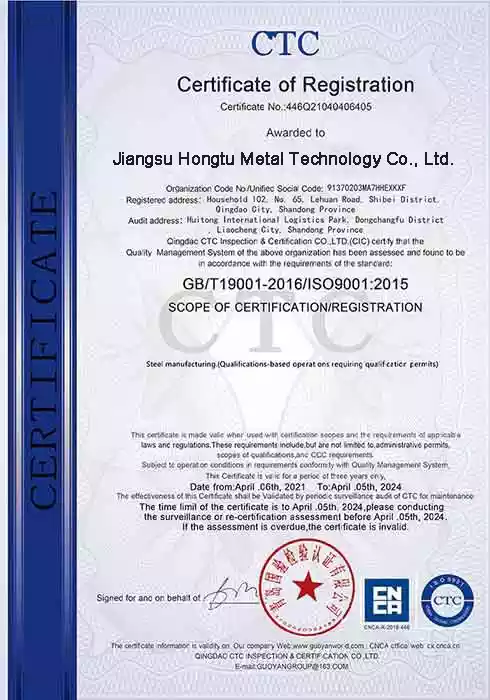

Qualification certificate