PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

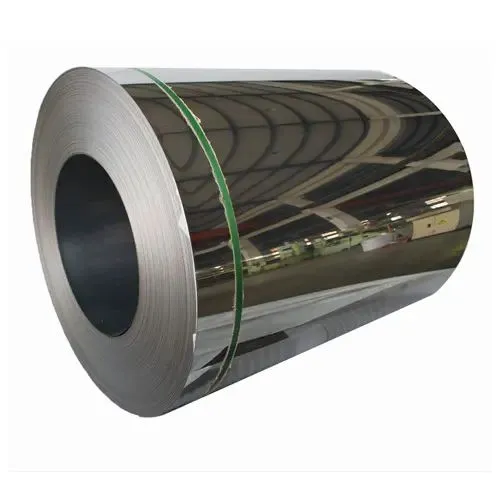

The 304H stainless steel coil offers distinct advantages, primarily due to its elevated temperature strength and superior corrosion resistance. Designed for high-temperature applications, it excels in industries like petrochemical, power generation, and aerospace, where resilience under extreme conditions is crucial. Its ability to withstand oxidation and aggressive environments ensures reliability in heat exchangers, boiler tubes, and furnace components. Moreover, its excellent weldability and formability streamline manufacturing processes, guaranteeing longevity and performance in demanding environments. Overall, the 304H stainless steel coil stands as a reliable solution for critical applications requiring durability and resilience at elevated temperatures.

The advantages of 409L stainless steel plate lie in its outstanding corrosion resistance, especially in environments prone to atmospheric corrosion, making it highly suitable for a range of applications. Its primary strengths include its ability to withstand high temperatures and corrosive elements, particularly in automotive exhaust systems, where durability is paramount. Additionally, its excellent formability and weldability characteristics make it versatile for various fabrication processes, ensuring ease of use and cost-effectiveness in industrial settings.

The advantages of 316 stainless steel round bar stem from its exceptional corrosion resistance, particularly in harsh environments exposed to chemicals and saltwater. Its composition with molybdenum offers superior resistance to pitting and crevice corrosion, making it an ideal choice for applications in marine, pharmaceuticals, and food processing industries. Furthermore, 316 stainless steel provides high strength, durability, and excellent weldability, ensuring reliability and longevity in various structural, mechanical, and decorative components. Its versatility and reliability make it a preferred material for critical applications where corrosion resistance and longevity are paramount.

The advantages of 317 stainless steel pipe stem from its exceptional corrosion resistance properties, particularly in harsh environments containing acids, chemicals, and saltwater. Its superior resistance to corrosion and pitting makes it ideal for critical applications in chemical processing, marine, and food processing industries. Additionally, its durability and aesthetic appeal contribute to its suitability for architectural, structural, plumbing, and automotive applications. Overall, 317 stainless steel pipe provides reliable performance and longevity in corrosive environments, making it a preferred choice for various industrial and commercial applications.

The advantages of 420 stainless steel round bar stem from its exceptional hardness, moderate corrosion resistance, and good machinability. Widely used in manufacturing cutlery, surgical instruments, and molds, its hardness and corrosion resistance properties are critical. Additionally, it finds application in industrial settings such as shafts, valves, and pump parts due to its strength and wear resistance. Its ease of fabrication and cost-effectiveness further enhance its appeal, making it a preferred choice for various consumer and industrial applications requiring hardness and machinability. Overall, 420 stainless steel round bar offers dependable performance and versatility, meeting diverse manufacturing needs with efficiency and durability.

The advantages of 409 stainless steel coil stem from its balanced combination of moderate corrosion resistance, high-temperature resistance, and excellent formability. Widely used in automotive exhaust systems, it provides durability and reliability in environments prone to corrosion, heat, and thermal expansion. Additionally, its versatility extends to architectural and structural applications, as well as household appliances, where its aesthetic appeal and ease of fabrication are beneficial. With its cost-effectiveness and reliable performance, 409 stainless steel coil offers practical solutions for various consumer and industrial needs requiring corrosion resistance and formability.

The advantages of 440 stainless steel round bar lie in its exceptional hardness, superior wear resistance, and moderate corrosion resistance. Widely utilized in manufacturing cutting tools, bearings, and surgical instruments, its hardness and wear resistance properties are critical. Additionally, it finds application in industrial settings such as molds, valves, and shafts due to its strength and resistance to wear. With its high carbon content enhancing hardness and edge retention, it ensures reliability and durability in demanding environments. Overall, 440 stainless steel round bar offers outstanding performance in applications requiring hardness, wear resistance, and corrosion resistance, making it a preferred choice for various industrial and manufacturing needs.

The advantages of 2520 stainless steel pipe stem from its exceptional corrosion resistance properties, particularly in aggressive chemical environments and high-temperature conditions. With its high chromium and nickel content, 2520 offers superior resistance to corrosion, oxidation, and high temperatures, making it ideal for applications requiring durability and reliability in harsh conditions. Its versatility allows for diverse applications across industries such as chemical processing, petrochemical, pharmaceutical, architectural, and marine. Overall, 2520 stainless steel pipe provides reliable performance and longevity, making it a preferred choice for critical applications where corrosion resistance and durability are paramount.

The primary use of a 410 stainless steel plate is in applications requiring moderate corrosion resistance and good mechanical properties. This type of stainless steel plate is commonly utilized in manufacturing components for automotive parts, industrial equipment, fasteners, and surgical instruments.