PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

430 stainless steel is used for building decoration, fuel burner parts, household appliances and household appliances. 430F is a steel with free cutting property added to 430 steel, mainly used for automatic lathes, bolts and nuts. 430LX adds Ti or Nb to 430 steel to reduce the content of C, which improves the processability and welding performance. It is mainly used in hot water tanks, hot water supply systems, sanitary appliances, household durable appliances, bicycle flywheels, etc.

310s stainless steel plate is widely used in kiln, high-temperature furnace, boiler, furnace liner high-temperature equipment, such as kiln car, boiler liner, high-temperature furnace, high-temperature furnace tube, combustion machine liner, etc. It can be used for high-temperature equipment. The product is resistant to high temperature and heat. 310s stainless steel plate has good creep strength and can work continuously under high temperature. The working temperature of 310S stainless steel is 1200 ℃, and it can work continuously at 1100 ℃. It is mainly used to manufacture high temperature exhaust pipe, high temperature furnace, high temperature furnace liner, crematory furnace and other steel grades requiring heat resistance, as well as high temperature and high temperature contact parts.

2507 stainless steel is used in oil and natural gas industry; Offshore stone skyshatter oil platform (heat exchanger pipe, water treatment and water supply system, fire protection system, water spraying system, water stabilization system; petrochemical equipment; desalination (desalination) equipment (and high-pressure pipe and seawater pipe in the equipment). Mechanical and structural components that require both high strength and high corrosion resistance: fuel (waste) gas purification equipment.

The advantages of 440A stainless steel plate lie in its high hardness, moderate corrosion resistance, and affordability, making it suitable for various applications. Its exceptional hardness and wear resistance properties make it ideal for manufacturing knife blades, cutting tools, and surgical instruments, where durability and sharpness are essential. Additionally, its moderate corrosion resistance ensures longevity in less corrosive environments, while its affordability makes it a cost-effective choice for applications where high hardness and moderate corrosion resistance are required.

The advantages of 409 stainless steel plate stem from its exceptional corrosion resistance in mildly corrosive environments, making it particularly well-suited for applications such as automotive exhaust systems and agricultural machinery. Its ability to withstand high temperatures and resist oxidation enhances its durability and longevity in demanding conditions. Furthermore, its excellent formability and weldability properties provide flexibility in fabrication processes, making it a cost-effective choice for a variety of structural and automotive components.

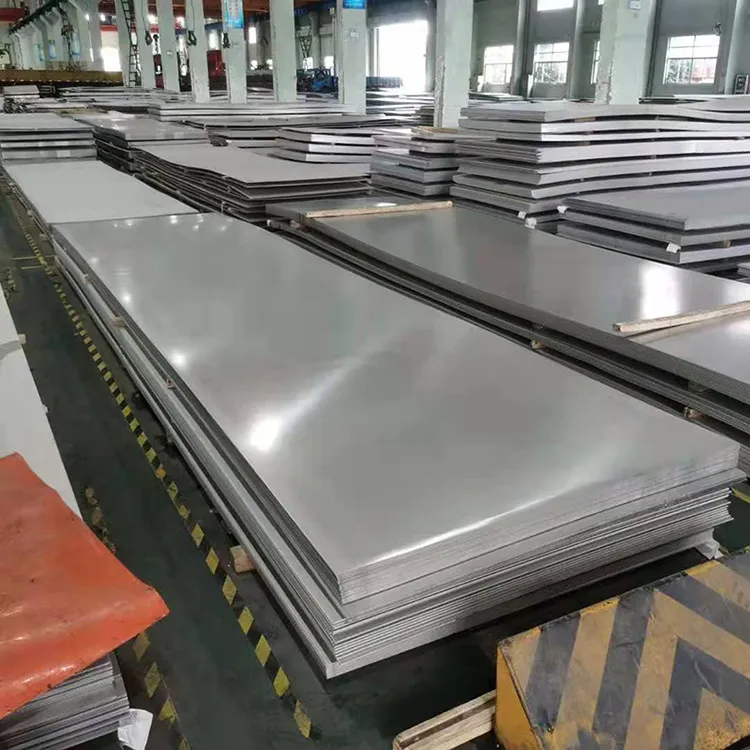

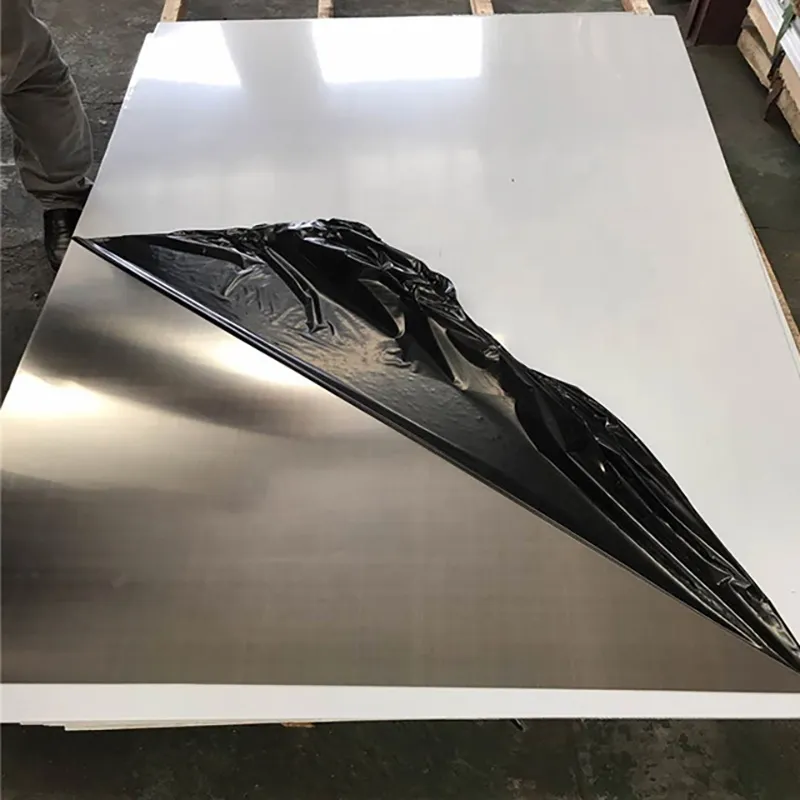

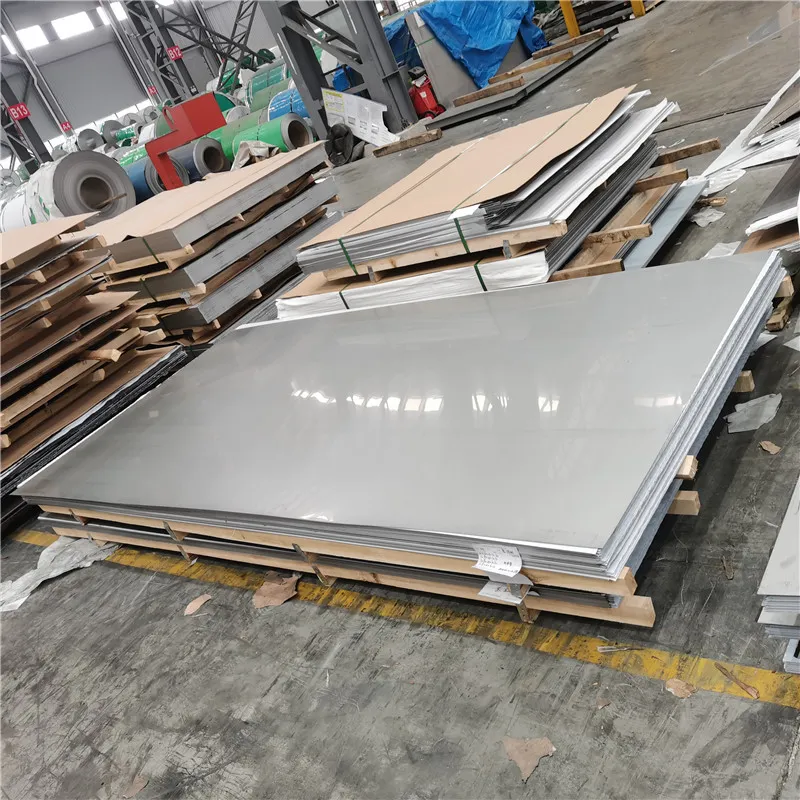

The advantages of 2B stainless steel plate lie in its smooth, matte finish, providing a clean and uniform surface appearance suitable for a wide range of applications. Its versatility makes it ideal for use in industrial equipment, kitchen appliances, and architectural structures where corrosion resistance is needed. Additionally, its non-reflective finish is advantageous in industries such as automotive trim and signage, contributing to its aesthetic appeal. The 2B finish offers consistency and reliability, ensuring durability and long-term performance in diverse environments.

The advantages of 904 stainless steel plate, or 904L stainless steel, lie in its exceptional corrosion resistance, particularly in aggressive environments containing sulfuric acid, phosphoric acid, and chlorides. Its superior performance in such harsh conditions makes it ideal for use in chemical processing equipment, seawater desalination plants, and offshore oil and gas platforms. Additionally, its resistance to pitting and crevice corrosion enhances its durability and reliability in critical applications where longevity and performance are essential.

The advantages of 301 stainless steel plate lie in its exceptional strength, corrosion resistance, and formability, making it highly versatile for a wide range of applications. Its high tensile strength and durability ensure reliability in demanding environments, while its resistance to corrosion makes it suitable for use in various industries, including automotive, construction, and manufacturing. Additionally, its excellent formability allows for easy fabrication into intricate shapes and components, further enhancing its usability and cost-effectiveness.

The advantages of 321 stainless steel plate lie in its exceptional corrosion resistance, high temperature stability, and oxidation resistance, making it a preferred material for demanding applications. Its resistance to intergranular corrosion and sensitization ensures durability in harsh environments, particularly in the presence of corrosive chemicals and high temperatures. Additionally, its ability to withstand elevated temperatures without significant deformation or degradation makes it ideal for use in exhaust systems, aircraft components, and chemical processing equipment, where reliability and longevity are paramount.