PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

The advantages of 309 stainless steel plate stem from its remarkable high-temperature strength and outstanding corrosion resistance, making it indispensable in demanding industrial applications. Its ability to withstand extreme temperatures and harsh environments, coupled with its resistance to sulfidation and carburization, ensures reliable performance in furnace parts, heat exchangers, and thermal processing equipment across various sectors including petrochemical, aerospace, and power generation.

The advantages of 316 stainless steel plate stem from its exceptional corrosion resistance, particularly in chloride environments, making it ideal for use in industries such as chemical processing, marine, and medical. Its superior resistance to pitting and crevice corrosion ensures durability in harsh conditions, while its excellent mechanical properties, including high tensile strength and toughness, enhance its suitability for a wide range of applications. Additionally, its versatility allows for easy fabrication and welding, contributing to cost-effectiveness and reliability in various manufacturing processes.

The advantages of 316H stainless steel plate are rooted in its tailored composition for high-temperature applications, providing exceptional creep strength and corrosion resistance. Its ability to withstand elevated temperatures makes it ideal for industries such as petrochemical, power generation, and heat treatment, where components endure harsh conditions. Additionally, its versatility extends to chemical processing equipment and automotive exhaust systems, where its durability and resistance to oxidation ensure reliable performance in demanding environments, enhancing operational efficiency and longevity.

202 stainless steel is one of 200 series stainless steel. 200 series stainless steel belongs to low nickel and high manganese stainless steel, with nickel content less than 4% and manganese content about 8%. In order to make austenitic stainless steel phase transformation, it must be heated to more than 1000 ℃, so at 350 ℃, the metallographic structure will not change, that is to say, the properties of the steel will not change sharply. It can only expand due to heating, but the amount is very small, which can be ignored in general. Therefore, 202 stainless steel strip has good high temperature resistance.

The advantages of 409S stainless steel plate stem from its heightened resistance to corrosion, particularly in mildly corrosive environments, rendering it highly suitable for diverse applications. Its primary strengths include its durability and longevity, especially in automotive exhaust systems where it withstands corrosive exhaust gases and high temperatures. Additionally, its excellent formability and weldability characteristics make it versatile for various fabrication processes, ensuring ease of use and cost-effectiveness in industrial settings.

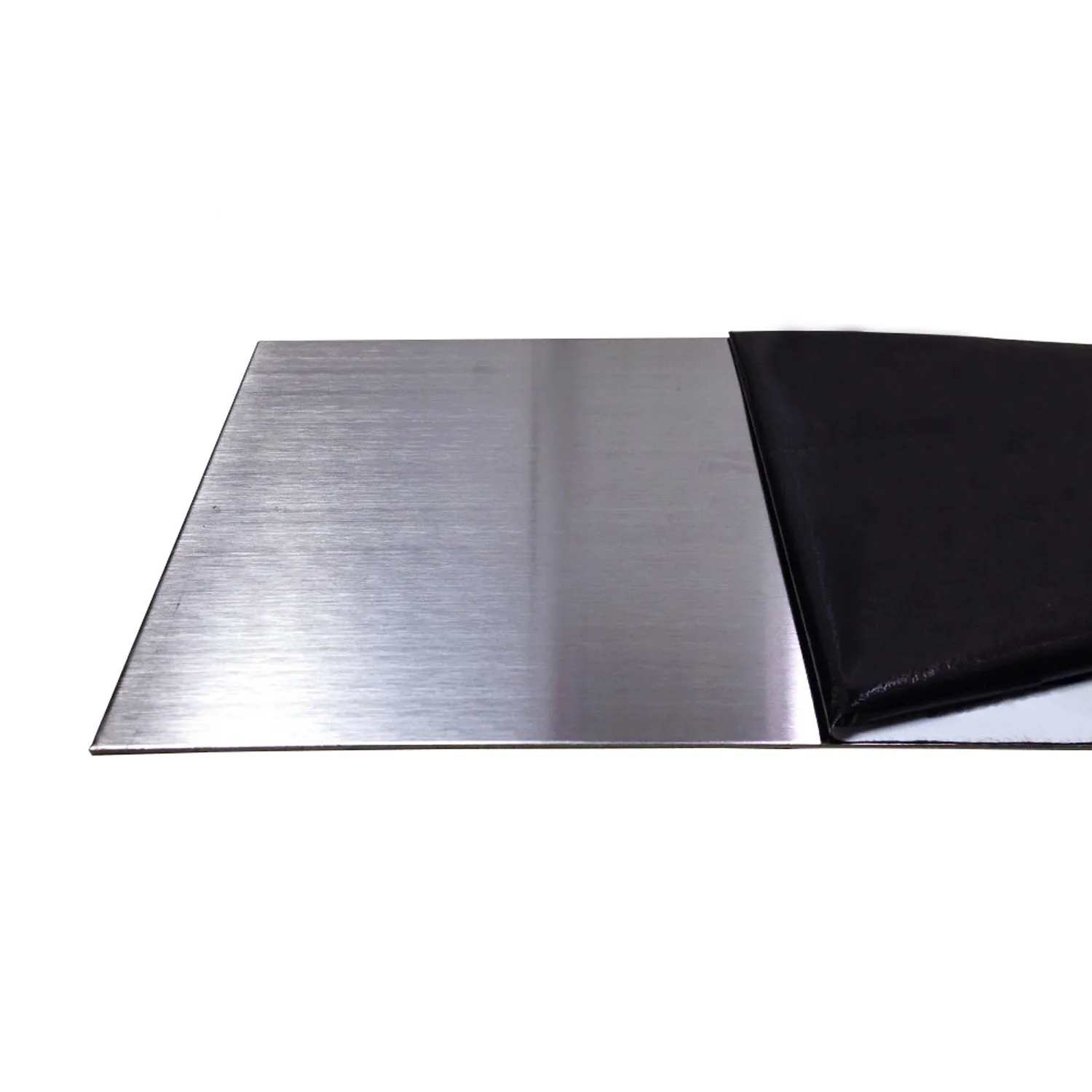

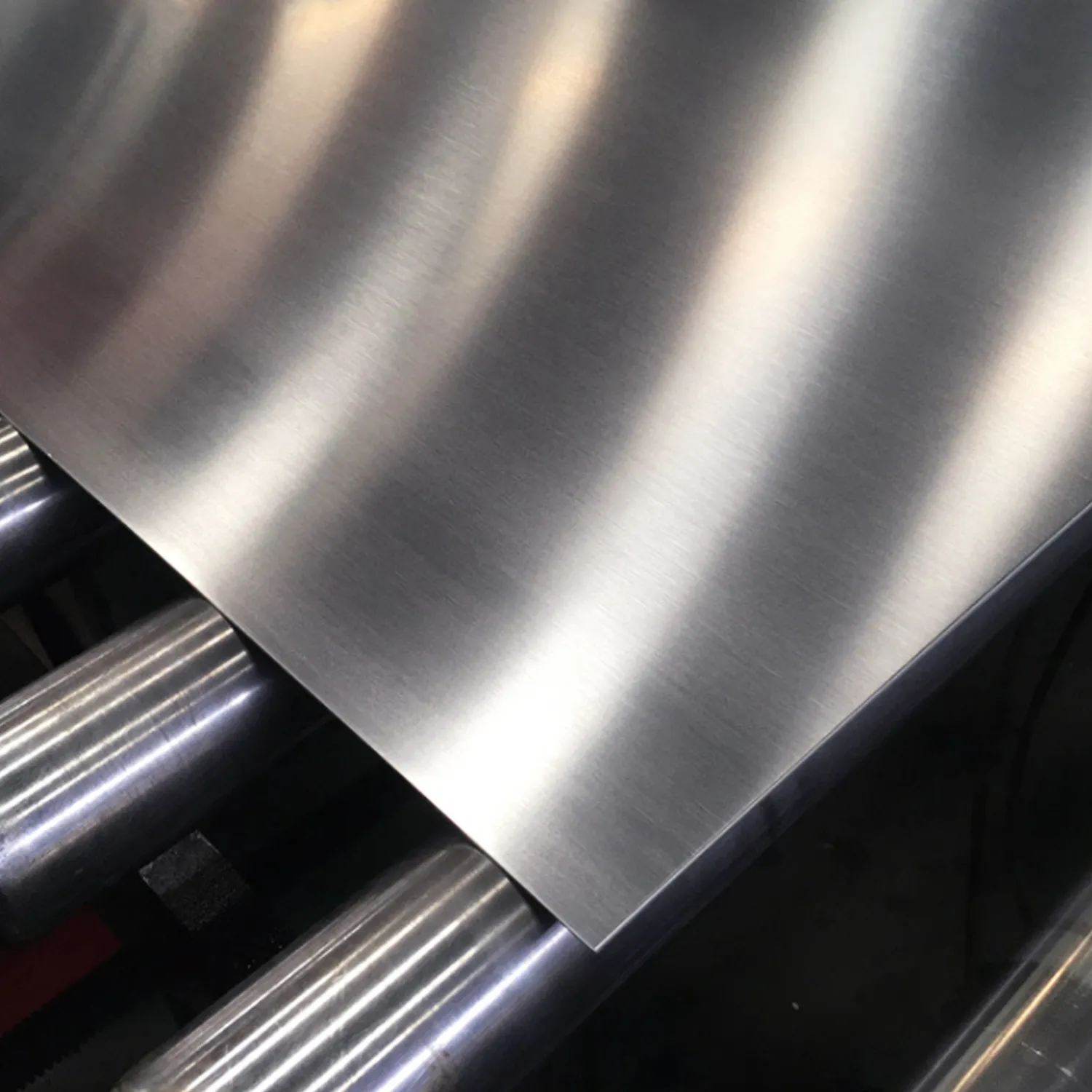

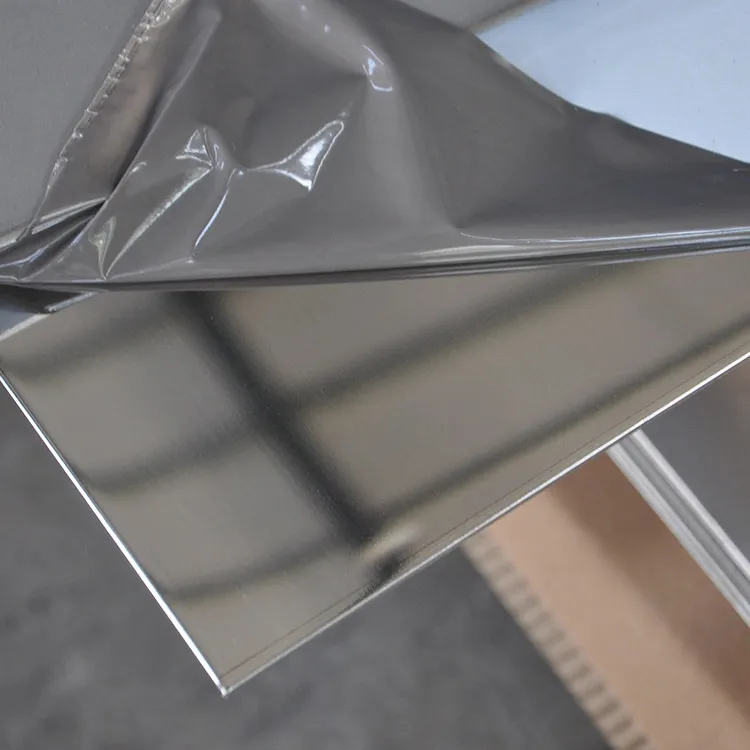

The advantages of No. 4 stainless steel sheet stem from its satin or brushed finish, which offers a sleek, contemporary appearance suitable for architectural and decorative applications. Its smooth texture not only enhances aesthetic appeal but also provides an easy-to-clean surface, making it ideal for environments where hygiene is paramount. Additionally, its corrosion resistance properties ensure durability and longevity, making it a practical choice for interior and exterior decoration, kitchen appliances, and commercial spaces requiring both style and functionality.

The advantages of 1.4529 stainless steel plate, or Alloy 926, lie in its exceptional corrosion resistance and high strength properties, particularly in aggressive environments. Its superior performance in resisting corrosion from sulfuric acid, chloride-containing environments, and other corrosive substances makes it ideal for critical applications in chemical processing, marine, offshore, oil and gas, pharmaceuticals, and pulp and paper industries. Additionally, its durability and reliability ensure longevity and optimal performance in demanding conditions, making it a preferred material for various industrial applications requiring exceptional corrosion resistance and high strength.

The advantages of 440 stainless steel plate lie in its exceptional corrosion resistance, high hardness, and strength properties, making it suitable for a wide range of applications. Its superior resistance to corrosion ensures longevity and reliability in harsh environments, while its high hardness contributes to excellent wear resistance, making it ideal for tooling, cutlery, and knife blades. Additionally, its strength characteristics enable it to withstand heavy loads and extreme conditions, ensuring durability and performance in various industrial settings.

The advantages of 630 stainless steel plate, also known as 17-4 PH stainless steel, stem from its exceptional combination of high strength, corrosion resistance, and ease of fabrication. Its unique properties make it well-suited for demanding applications in aerospace, defense, and chemical processing industries, where structural integrity and resistance to corrosion are paramount. Additionally, its versatility extends to medical devices, marine equipment, and industrial machinery, where its durability and reliability contribute to enhanced performance and longevity in challenging environments.