PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

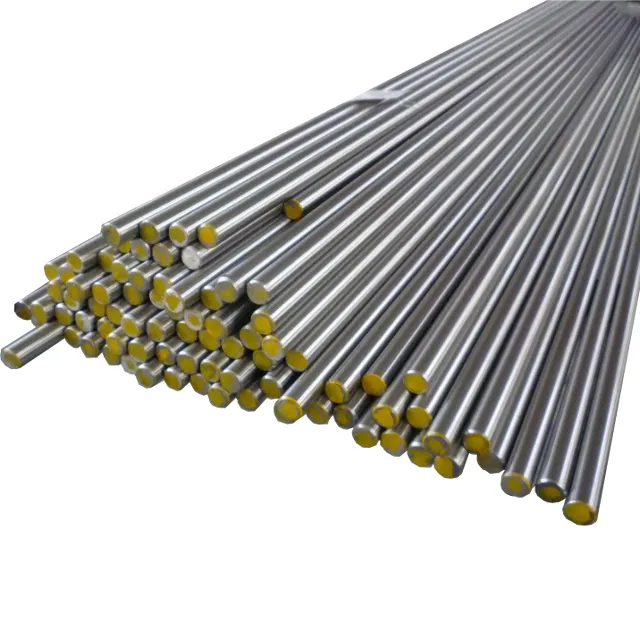

2205 Stainless steel round bar

2507 Stainless steel round bar

904L Stainless steel round bar

316ti stainless steel round bar

440C stainless steel round bar

317l stainless steel round bar

304h stainless steel round bar

2520 stainless steel round bar