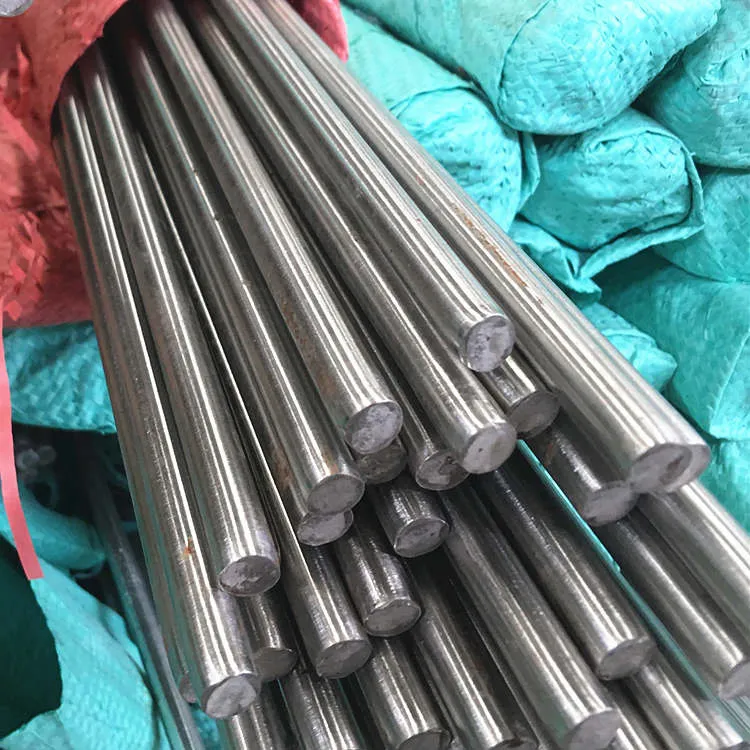

610 stainless steel round bar

The advantages of 610 stainless steel round bar lie in its exceptional strength, excellent corrosion resistance, and good formability. Widely used in marine equipment, chemical processing, and architectural structures, it offers durability and reliability in environments prone to corrosion. Additionally, its versatility extends to automotive parts, aerospace components, and household appliances, where its durability and aesthetic appeal are beneficial. With its ease of fabrication and weldability, it serves as a preferred material for various consumer and industrial applications requiring strength and corrosion resistance. Overall, 610 stainless steel round bar delivers dependable performance and versatility, meeting diverse manufacturing needs with efficiency and durability.